Phased Array ultrasonic testing (PAUT) is an advanced NDT method used widely in several industry sectors, such as construction, pipelines, and power generation. Phased Array is used to detect discontinuities such as cracks or flaws and thereby determine component quality. Due to the possibility to control parameters such as beam angle and focal distance, this method is very efficient regarding the defect detection and speed of testing. Apart from detecting flaws in components, phased array can also be used for wall thickness measurements in conjunction with corrosion testing.

Applications

Phased Array ultrasonics has many different applications such as weld inspection, corrosion mapping, bolt and nozzle inspection. Glacier Energy specialises in the use of Phased Array for the construction of new piping, pipelines, vessels, and structural welded members. This technique can also be used in petrochemical plants for “in service” applications, when quick and accurate inspections are necessary due to time constraints during outages.

Methods

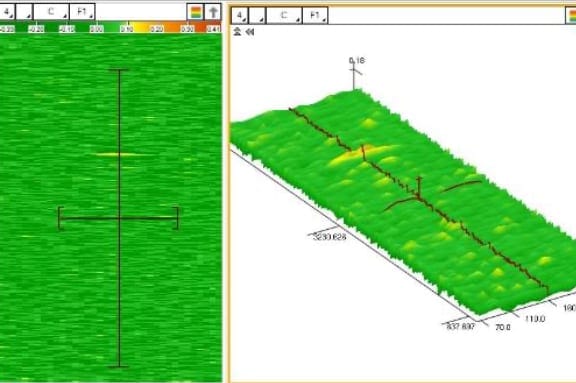

Phased Array ultrasound inspection methods use a probe with one transducer effectively “sliced” up to create multiple small transducers that are pulsed individually to control the focus and sweep of the beam. Software controls the timing of the pulses. The reflected pulses are processed and combined to create an image of any flaws or defects found in the material being inspected. Optimised beam focus and angle enable rapid scanning without transducer positional movement, i.e. from a fixed distance or position, allowing inspection from multiple angles, and the ability to inspect materials with complex geometries.