Overview

Products

Glacier Energy is a specialist provider of onsite machining equipment for sale and rental. We have an established global track record delivering major projects across the energy sector, for both topside and subsea applications and well as onshore sectors including construction yards, petrochemical and power generation.

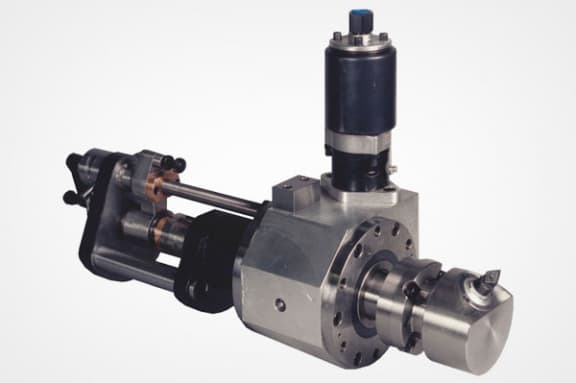

In 2011, Glacier Energy acquired Roberts Pipeline Machining, renowned specialists in the design and manufacture of precision on-site portable cutting machines since 1952. Today, the Roberts Pipeline Machining name remains synonymous with the highest standards of precision, efficiency, quality and reliability. The company also founded the ‘Clyde’ product range which set the benchmark in pipe cutting technology when it was first introduced to the market over 40 years ago.

This history and heritage showcases the strength and depth of Glacier Energy’s machining capability and why we continue to be the go-to partner for our clients’ onsite precision machining requirements.

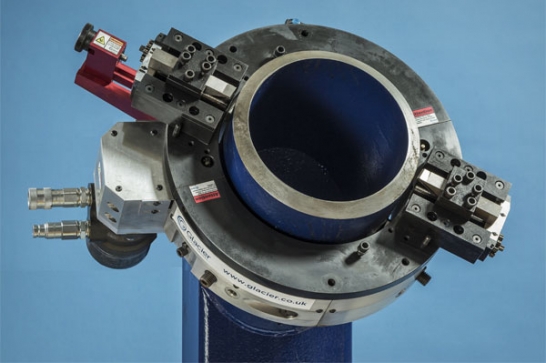

We offer precision machining equipment in various ranges for subsea and topside applications for use in spool bases, pipe coating yards and on pipelay vessels. Our equipment is renowned for its accuracy of cut, 100% rigidity during cutting, efficiency, ease of maintenance, decontamination and longevity.

Need advice or help with your Machining requirements?

Do you want further details about our wide range of Machining products and services? You can call us on 01333 425517 or fill out the form below and we'll get back to you.