Heat exchangers are integral to many industrial processes, with their primary purpose being to conserve energy by passing heat from one process stream to another. During operation, heat exchangers undergo the process of fouling, whereby solid materials are deposited on the heat exchanger surfaces. The build-up of this material affects the performance of the heat exchanger, acting as a barrier to heat transfer and causing it to operate less efficiently than it was originally designed for. Over time, this leads to increased operating and maintenance costs and can even cause expensive unplanned downtimes due to failure of the heat exchanger.

Fouling also presents another major issue to operators: increased carbon emissions. Any loss of heat transfer needs to be compensated for elsewhere in the process, primarily through additional heating or cooling, meaning more energy needs to be put into the system and, therefore, more CO2 is emitted. The power to pin-point and quantify any loss of efficiency of a process is quickly becoming a “must-have” capability as the energy industry continues its drive towards a Net Zero future.

HTX Digital

As heat exchanger experts, we at Glacier Energy believe there is a smarter way to monitor and manage the operation of heat exchangers. This is why we have developed HTX Digital - a digital non-intrusive monitoring tool that utilises existing data combined with predictive algorithms to trend and predict the future performance and degradation of heat exchangers.

HTX Digital consists of several calculation strategies, with each of these measuring or monitoring a different mode of degradation or failure mechanism of the heat exchanger. The calculations are implemented onto the HTX Digital platform, along with design information on the physical dimensions of the heat exchanger. The tool is then able to carry out calculations on large amounts of operational data, both historic and live, to monitor trends and measure the increasing level of fouling over time. By quantifying the resulting loss in energy efficiency, HTX Digital can help you reduce your operating costs and carbon footprint by promoting smarter decision-making and effective maintenance scheduling.

In addition, HTX Digital uses this method to detect probable instances of heat exchanger failure mechanisms that are not possible to measure directly, such as tube vibration, exceeding velocity limits, and thermal cycling.

Data Filtering

A colossal amount of data is being collected nowadays, but not all of it is useful. A major speedbump in the road to digitalisation is the lack of availability of reliable data, without which we cannot begin to tackle the issue of energy efficiency.

A first step in being able to obtain useful insights is to apply targeted filters to clean up the data. As well as more general filters, such as removing points where data is in the wrong format, HTX Digital applies specifically designed filters that target heat exchanger operating parameters. This includes instances of low-flow or similar entering temperature differences, which would negatively affect the accuracy of the results of the calculations that measure energy efficiency. This is an important step in making sure the digital tool provides accurate monitoring of the change of efficiency of the heat exchanger over time.

Tracking the Loss of Energy Efficiency Caused by Fouling

With industry continuing to move from reactive to proactive maintenance of assets, the ability to trend and predict optimum maintenance windows is becoming essential. For heat exchangers it is possible to track the loss in efficiency caused by fouling and combine this data with predictive algorithms that will indicate the most economically optimal time to perform cleaning of the heat exchanger to remove the fouling deposits.

The build-up of a foulant layer on the walls of the heat exchanger adversely affects the efficiency of the heat exchanger. There are two ways in which is does this: 1) adding resistance to heat transfer across the heat exchanger walls, and 2) narrowing the free-flow area of the heat exchanger, meaning more power is required to pump fluids through.

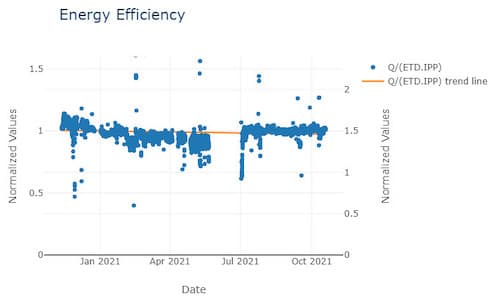

HTX Digital combines these two variables into a single parameter, which allows the user to gain insight into the changing efficiency of the heat exchanger by plotting, versus time, a parameter analogous to the quantity of heat transferred per unit of pumping power required to operate the heat exchanger.

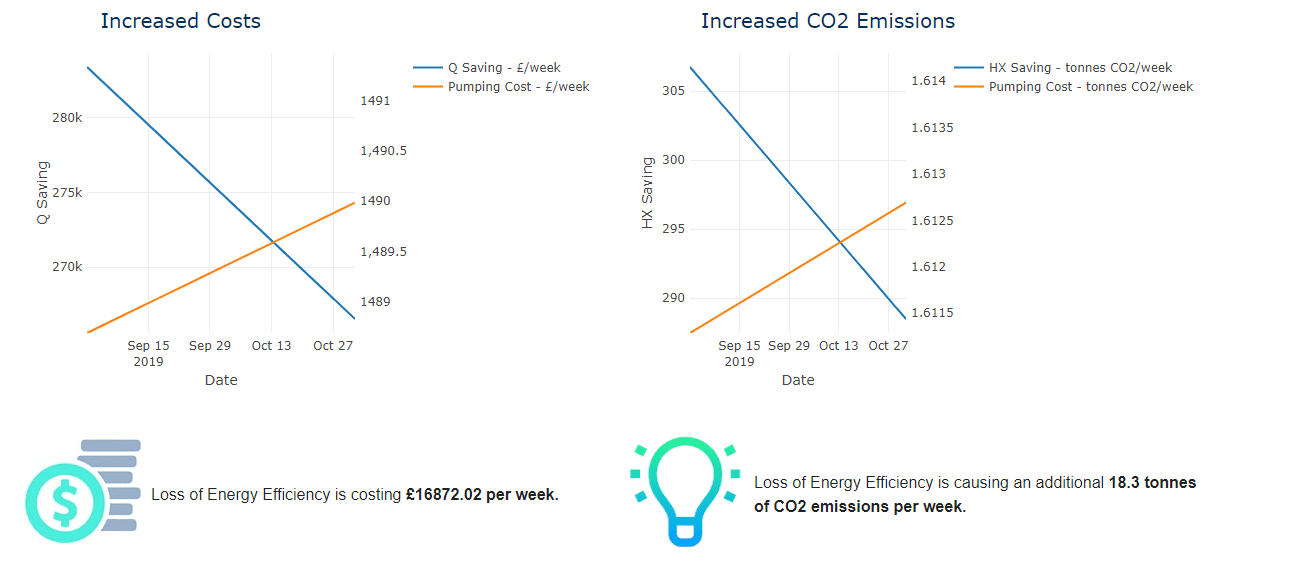

With the drop in energy efficiency quantified, HTX Digital can convert this into tangible values for the increased operation costs and emissions of carbon due to additional heating or cooling required. This is a valuable tool for assisting in the decarbonisation of your process or asset.

Predicting the Best Time for Intervention

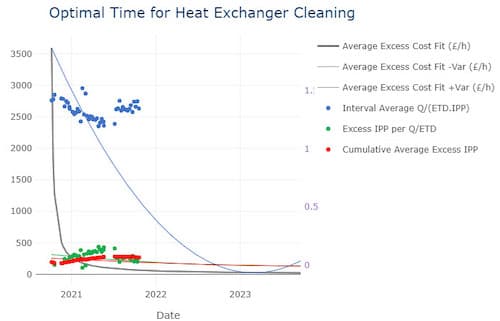

The drop in energy efficiency of the heat exchanger over time can be used to determine the optimal time to clean. By combining the cost of cleaning of the heat exchanger with the increased operation costs, HTX Digital’s in-built predictive algorithms trend and extrapolate the increased costs over time. The resulting curve produced is essentially a trade-off between these two costs, where the minimum point can be taken as the most economically beneficial time to perform cleaning.

This ability to predict the optimal time for cleaning allows the heat exchanger maintenance schedule to be taken from reactive to proactive, resulting in less unplanned asset downtime and cost savings by up to 30%.

Don’t be left behind on the journey to digitalisation. Get in touch with us if you would like to receive any more information, or to request a demo of how HTX Digital can help you with your heat exchanger management.