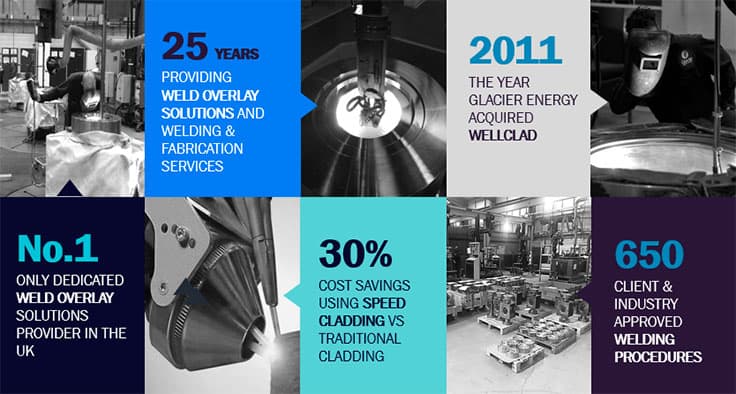

For over 20 years, Glacier Energy has been providing specialist corrosion resistant alloy (CRA) weld overlay solutions and welding and fabrication services to clients worldwide.

In 2011, Glacier Energy acquired MB Wellclad, a renowned weld overlay and cladding services provider for offshore subsea equipment since 1997. Over the years, Glacier Energy has continued to strengthen its expertise across the energy sector to become the go-to partner in the provision of world-class welding solutions based on our proven track record and commitment to the highest quality standards.

As pioneers in our field, we also strive to remain at the forefront of the industry by applying the latest innovations and techniques in order to reduce project lead times and pass on further cost efficiencies to our clients. Operating from a purpose-built Centre of Excellence facility in Glasgow, as well as from a strategic operating base in Newcastle, Glacier Energy has a vastly experienced management team and welders qualified to the highest industry standards.