In 2014, Glacier acquired Professional Testing Services (PTS), an industry-leader of non-destructive testing (NDT) and inspection services.

To date, we have delivered over 800 NDT & inspection projects world-wide. Our team includes over 100 trained and qualified inspection personnel with PCN (ISO 9712) qualifications at L2 and L3 in ultrasonic testing, radiographic inspection, surface inspection (MPI and DPI) eddy current welds and forgings (tubes), ToFD, PAUT, ACFM and visual inspection.

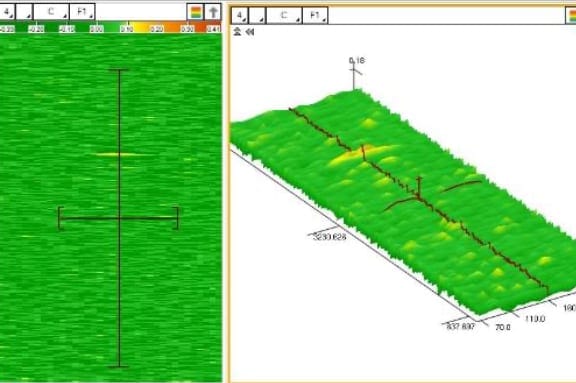

From inspecting standard equipment to complex geometries, we provide you with the solutions required to gather data needed to make informed decisions about your critical assets and infrastructure.